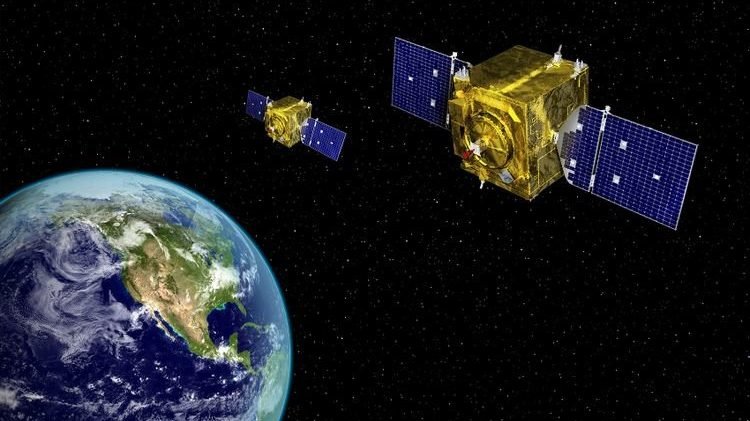

Two Northrop Grumman Corporation Geosynchronous Space Situational Awareness Program (GSSAP) satellites were successfully launched into orbit on a United Launch Alliance (ULA) Atlas V rocket on January 21 from Cape Canaveral Space Force Station as part of the U.S. Space Force (USSF)-8 mission.

The two satellites, GSSAP-5 and GSSAP-6, will enhance space situational awareness, a top priority for the U.S. Space Force. In addition to manufacturing and delivering both GSSAP payloads, Northrop Grumman also provided the sole strap-on solid rocket booster adding propulsion to the rocket launch, as well as essential aeronautical components in support of the USSF-8 launch.

The GSSAP program delivers a space-based capability operating in a near-geosynchronous Earth orbit (GEO), in support of the U.S. Space Command space surveillance operations. GSSAP satellites allow for more accurate tracking and characterization of orbiting objects and uniquely contribute to timely and precise orbital predictions, enhancing knowledge of the GEO environment and improving spaceflight safety. Northrop Grumman has manufactured all GSSAP satellites since the program’s inception in 2011.

“For over a decade, Northrop Grumman has delivered products that improve U.S. Space Command’s ability to monitor human-made orbiting objects in the geosynchronous environment,” said Matt Verock, vice president, space security, Northrop Grumman. “As dedicated Space Surveillance Network (SSN) sensors, the capabilities our GSSAP satellites bring demonstrate our leadership in space domain awareness.”

The company’s facilities in Dulles, Virginia along with Goleta and San Diego, California, and Beltsville, Maryland provided numerous subsystems, including the satellite’s solar arrays, primary structure, thermal control, avionic boxes, flight computer, shunt regulator assembly, composite components and deployable structures.

This was the third ULA Atlas V rocket launch supported by Northrop Grumman’s 63-inch-diameter Graphite Epoxy Motor (GEM 63). The GEM 63 solid rocket booster, manufactured at the company’s Magna, Utah facility, provided nearly a third of the total thrust at liftoff. The GEM family of solid rocket motors recently expanded with the development of the GEM 63XL variation to support ULA’s Vulcan Centaur launch vehicle, scheduled for its first flight later this year.

The company manufactured the Atlas V rocket’s reaction control system propellant tanks at its Commerce, California, facility, and eight retro motors at its Elkton, Maryland, facility that assist first and second stage separation. Using advanced fiber placement manufacturing and automated inspection techniques, Northrop Grumman produced the composite heat shield that provides essential protection to the Atlas V first-stage engine, the Centaur Interstage Adapter that houses the second-stage engine, and the broadtail that adapts from the core vehicle to the five-meter diameter fairing. Northrop Grumman fabricated these structures at its Iuka, Mississippi, facility.